Injection Mold Quote

How to Complete a Project for Plastic Injection Molding Quotes

2021年6月24日

Automotive Plastic Parts Manufacturers

2021年7月8日How to get a plastic injection mold quote

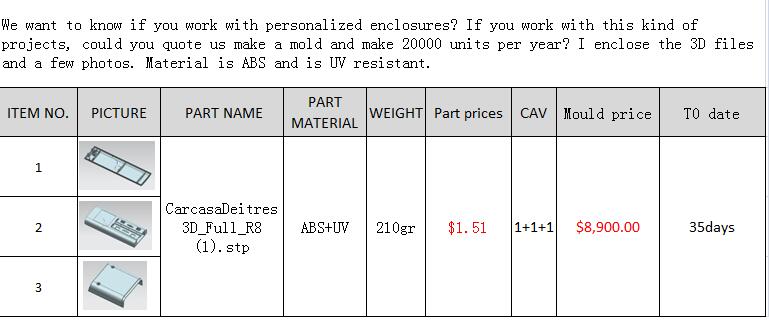

An empirical calculation method injection mold quote = material cost + design fees + profit + VAT + test mold fee + packing and shipping fee in China. The ratio is usually as follows:

The injection mold company cost of materials:

1)Materials and standard parts accounted is 15%

2) Processing fees and profits is 30%

3) Design Fee: 10%;

4)Tax of the total cost of the injection mold company to 15%.

5)Setup machine for test mold fee: 5%

6)Packaging and Shipping cost: 25%

Certain variable data

Tryout large and medium-sized injection molds can be controlled within 3%, and small precision injection molds are controlled within 5%. Packaging and transportation costs: according to the actual calculation or 3%. VAT: 17%

1, the material coefficient method

The injection mold company material cost can be calculated according to the injection mold size and material prices. Injection mold company price = (6 ~ 10) * Material fee insert and slider.

plastic mold = 6 * The cost of materials

Die-casting mold = 10 * materials fee Injection mold company quotation estimates. A first look at customer requirements, calling for a decision on the choice of materials and heat treatment.

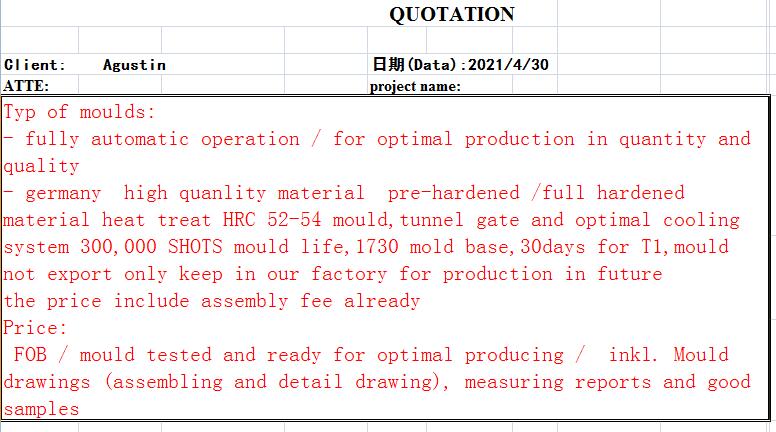

2, Material and Heat

A rough injection mold program map, from which to calculate the injection mold weight, plus mold base weight and core/cavity weight, and heat treatment costs.

3, Tooling Quote

According to the complexity of the mold structure, the general tooling cost, and the price ratio of the mold core material are 1.5-3: 1, and the tooling cost and material ratio of the mold are generally 1: 1.

4, Risk

The actual molds cost is often higher than the quoted cost. We are commonly called the plastic mold quote risk and uncertainty. The formula-calculated design cost is 10% of the total mold amount. Bidding strategy and scheme of the mold project.

The actual mold payment purchase is a the mold evaluation verification results. From the mold valuation to the mold quotation, only the first step, the mold is delivered to settlement through the mold fabrication final goal . There are many variables in the formation of the mold final settlement price, so we usually recommend for you leave a 5-10% fluctuation space.

Valuation of the mold

In this process, people always want the valuation of mold quote = mold price = mold settlement price. In practice, the third prices are not exactly equal, there may be fluctuations in error. This is to be discussed below.

When the valuation of the mold, the need for proper handling, finishing into an injection mold quotation. signed a mold contract basis. Through repeated negotiations to discuss the final form of the mold price, both sides recognized the signing of the contract. To officially start the processing of the mold.

After the mold is completed, the plastic injection molding quote, see another article for this introduction.

Really Injection mold cost price in China

Many customers need a plastic injection mold estimate at the start of the project. Although this is difficult to have a uniform standard. We try to give you some price information.

Prototype Mold Price

These molds are one cavity, the material of aluminum mold or low-quality steel mold. Price around $ 1000 for 2 weeks.

Mass production of the mold

Whether single or multi-cavity mold, calculated by mold size. $ 3000-5000 mold around 250KG

About 500KG mold for $ 8000- $ 10000.

Precision Export Mold

This kind of mold mainly sees precision. Higher the precision injection mold price, you can not only look at the size.

General Precision mold $ 12000 High Precision mold $ 30000

The most challenging is that large precision injection molds can cost $ 500,000 and have no cap.

The above price is based on a medium-sized, professional Chinese injection molding manufacturing cost. Relative comparison, if you purchase the mold in Europe and America, it will be about 6 times the price.

Injection Mold Quote Step

First

In the case of ensuring that the enterprise has a profit, in line with the ability of the company, the final price of the mold. The mold offer was once accepted by both parties, and the contract payment conditions were signed. At this point, injection mold quotes may be above or below valuation. The mold cost is higher than the price negotiated by the mold, and the commission is required to prompt the subsequent maintenance cost of the mold, and choose some technical options that may reduce the cost of mold processing to improve the mold price contract.

One-sided customers pursuing low prices are not the target customers. Injection molds belong to customized products, with higher technical content. In order to win the order of excessive price reduction, and ultimately can not meet the customer product requirements. Good quality and a cheap price. To ensure the quality, accuracy and life of the mold, these conditions are originally contradictory. What the injection molding manufacturer needs to do is find the balance.

Second

In the pursuit of mold cheap, it is difficult to guarantee the quality, accuracy, life of the mold. Cheap is not generally the mold industry. However, when the mold manufacturing and product development and production of the same accounting unit, or economic interest. In this case, the purchase of the mold should be its cost price as a quotation. The valuation of the mold only to estimate the basic cost of part of the mold and other costs. The profit not to consider, be the profit of the products produced after extraction of the added value of the mold fee as compensation.

At this time offer can not be used as the price of the mold, only as a mold pre-development quote. In the future, once the products successfully developed to generate profits, you should extract the added value of the mold fee. It was returned to the mold manufacturing units, two together, to form the price of the mold. the formation of mold price may be higher than the price of the first investment, and even high rates of return, which is several times the normal mold price, ranging from several hundred times. Of course, there is a possible rate of return equal to zero.

Third

Injection mold quotation should also be noted that the valuation and price of the mold in various enterprises, various regional, national. At different times, in different environments, its meaning is different. there are regional differences and time differences.

Why would the plastic mold quote different, this is because the one hand, enterprises, regional, national injection molds manufacturing conditions are not the same, equipment, technology, personnel concepts, consumer standards in all aspects of the different. resulting in the cost of the mold, profit targets, estimates vary, resulting in a different mold price difference.

Fouth

Generally speaking, more developed fields, or high-tech and equipment to enter the more advanced, more standardized large mold manufacturer. They advertise in high quality and high prices. Small and medium-sized mold companies. The relative mold prices are estimated to be lower.

But the fact is that the best mold company is not a large mold manufacturer. It is a small and medium-sized mold company with about 30 people.

The more professional mold company, the number is unlikely to be. Only skilled mold engineers can complete high technical molds.