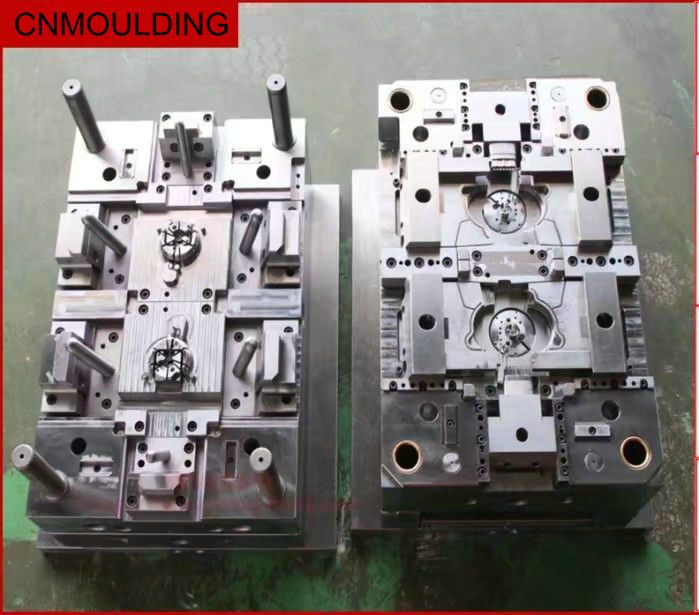

Injection Mold Types

Quality Control

2020年6月26日

mould maker

2020年6月28日Plastic injection mold types in China

There are 4 main commonly plastic injection mold types to be used. The name is color runner mold, two plate injection mold, three plate injection mold, and hotter runner mold. Plastic injection molds to create objects, injection molding plastic is forced into the mold cavity. They are often used to scale manufacturing operations, creating new products, such as toys, kitchen utensils, caps, mobile phone sets. You can use the injection mold “flash line” extra plastic around the seams discovery projects.

TYPE 1: Cold runner mold

Cold runner mold, such injection mold types is the most common way. The gates and runner mold used for injection molding plastic in each mold cavity. However, the sprue and runner and some hardened once solidified. Workers then work and recycling. This may cause the waste problem, which may make their economic use.

TYPE 2: Two plate plastic injection molds

Two plastic cold runner mold is so named because they are characterized by two plates together. Only a parting surface that must be located in the runner. This is the easiest cold runner mold.

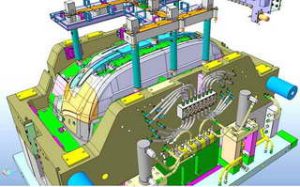

TYPE 3: Three plate plastic injection molds

Three plastic cold runner mold has three, which means that there is one pair of parting planes. Three of the manifold, the movable plastic, and floating panels. it contains half of the gate hot runner plate and the runner-up. The injection system comprising half of the movable plate and the geometric shape of the part. The other half of the rotor included in the floating plate and geometry. The system can be located in any of the partings, and anywhere on the surface can be selected through the sheet to provide flexibility.

TYPE 4: Hot runner mold

Hot runner mold provides a different way of injection mold types. As part of the runners, although a plastic syringe and cool the cold runner, the hot runner mold in the mold and stored in the temperature higher than the melting point of the plastic. This means that the gate and runner sclerosis will never have a chance. This also reduces the amount of plastic waste. However, the hot runner injection mold requires more skill and maintenance, and have a higher baseline cost. However, they tend to save materials according to their own.

Above are four main injection molds types in China