What about a Hot Runner Mould

Best iPhone Accessories Manufacturer in 2019

2021年6月10日

Refrigerator Plastic Parts Injection Molding and Mold Making

2021年6月14日About Hot Runner Mould

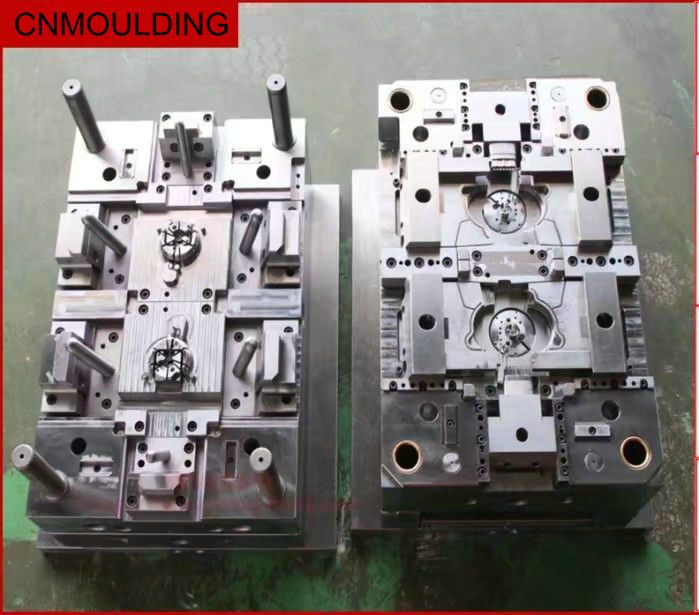

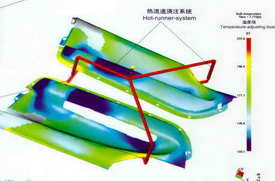

A hot runner system is an assembly of heated components used in plastic injection molds that inject molten plastic into the cavities of the mold. The cavities are the part of the mold shaped like the parts to be produced.

CNMOULDING hot runner mould maker take last technology about Incoe hot runner in 2020 ( see video)

Hot runner systems were first developed and came into sporadic use in the early 60s with generally negative results. They gained popularity in the 80s and 90s as technological advantages allowed improved reliability and the escalation of plastic materials prices made hot runner systems more desirable and cost-effective.

Hot runners are fairly complicated Manufacturing systems.

They have to maintain the plastic material within them heated uniformly, while the rest of the injection mold is being cooled in order to solidify the product quickly. For this reason, they are usually assembled from components premanufactured by specialized companies. Two main types of hot runner systems are externally heated and internally heated. In the externally heated type, molten plastic runs within a solid manifold and within the nozzles. In the internally heated, (now obsolete) the plastic flows directly over slender heaters inside oversized runners. The outside boundaries of the runners normally solidify, so the plastic material flows only in the proximity of the internal heaters or “torpedoes”. A hot runner controller is a temperature controller used to control the temperature in the hot runner. This helps create the most consistent part(s).

“Retains” and “Reduce”

Saving the raw materials and reducing the product cost are the most significant characteristic of the hot runner mold. A large amount of material handle should be produced in the ordinary pouring system, and the weight of the pouring system condensate may exceed the weight of the product. Because the plastic has been in the melting state in the hot runnermold, the products do not need to cut the gate, it is basically no waste processing, so it can save a lot of raw materials. Because there is no need for waste recycling, selection, crushing, dyeing and other processes, so hot runner mould usually makes the mold more expensive to manufacture and run, but allow savings by reducing plastic waste and by reducing the cycle time.

It uses an assembly of heated components in plastic injection molds that inject plastic into the cavities of the mold. There are two general types of runner fewer molds – the insulated system and the hot runner system.

Runner system over conventional cold runner system and eliminate a number of the disadvantages. A hot runner system is one of the more important enhancements you can incorporate into a mold to improve molded part quality. It will help reduce production times and remain price competitive

Material Type

Hot runner molds have been successfully used to process various plastic materials. Such materials like PP, PE, PS, ABS, PBT, PA, PSU, PC, PC, POM, LCP, PVC, PET, PEI, ABS / PC etc. Any plastic material that can be processed with cold runner mold , it can be processed with hot runner mould also.

Dimensions and Weight

Parts manufactured with hot runner minimum less than 0.1 g. The largest is below 30 kg. Very broad and flexible application

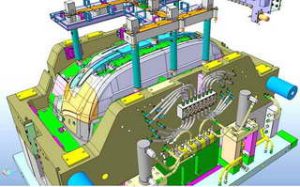

How we design a Hot runner injection mold

Injection Mold maker with Hot runner Solution will use a reliable hot runner system and mold design tools. Our engineering department works harder and quicker than any other supplier to offer you new design ideas and mold concepts using any kind of hot runner system. with a long history of experience and reliability for plastic injection molding and hot runner mould manufacturing, we can deliver the best solutions.

Although there are many hot runner manufactures, a few major components the same:

- Hot runner plate (MANIFOLD)

- Nozzle

- Temperature Controller

- Auxiliary parts

Advantage of hot-runner mould in the injection moulding industry

Why some customers select hot runner to make an injection mold. This is mainly due to such injection mold has following salient features:

Less plastic raw materials: in the age of expensive oil and raw materials. hot runner technology is an effective way to reduce the materials cost.

Quickly cycle time for injection molding: Due to no cooling time constraints runner system. Plastic can be a more uniform state injection into each cavity, the result is consistent quality parts. Such injection molding components of good quality and low residual stress after ejection part distortion.

Reduce product costs: improve product quality. Relatively speaking, the hot runner has a disadvantage.