China Plastic Injection Moulding company for Custom Plastic Molds Solution Since 1997

Tour our Facility

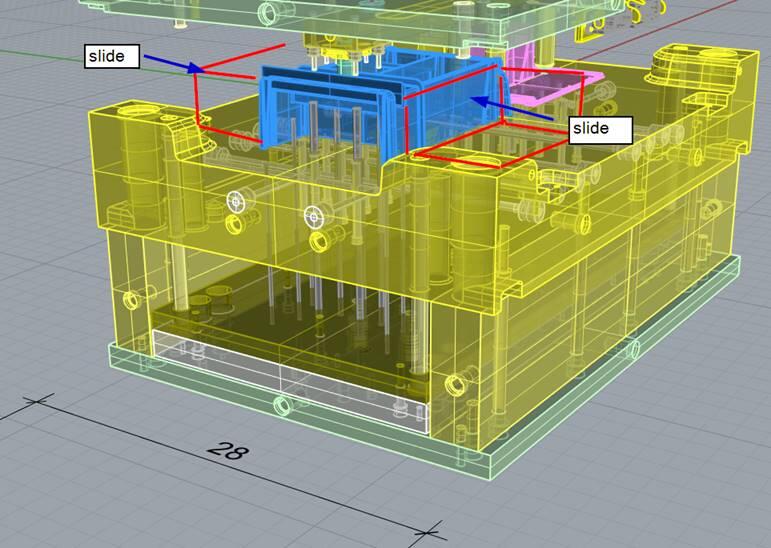

3D Software Full Advanced Engineering Plastic Injection Moulding Design Services

We get the project management experience you deserve with high-level quality

Do you know really a Chinese injection mold company’s working process?

Plastic Injection Moulding Frequently Asked Questions Wiki on

how to find a good Chinese injection molding supplier?

However, if we want to have a substantive discussion and ask for what time to select the injection molding supplier, before making your decision, look at our proposal, you must be inspired.

How to save mold cost 30% more in China?

the most common question, when my customer asks plastic injection molding manufacturers

is: “how to help me save more cost of my plastic injection mold, even up to 30%?” and ” how do complete an injection molding quote ?”

What is overmolding?

Overmolding is the plastic injection moulding process where one material (usually like soft plastic material TPE/TPR/TPU) is molded onto a second material (typically a rigid plastic, Like ABS).

What is insert molding?

Insert molding is the plastic injection molding process where one material (usually like a metal insert ) is molded onto a second material (typically a rigid plastic, Like ABS or PC, or Nylon). In some cases, inserts can be as complex as pipes or motors.

Why we are the best iPhone Accessories Manufacturer?

we provide plastic injection moulding part of your new iPhone accessories. Our creative fast mobile phone accessories custom service independent of any other Chinese plastic injection mold manufacturer.

How does the injection mold part quality inspection?

100% plastic Injection molded parts quality inspection methods In China. Whether produced after injection products meet quality standards, must be tested, common quality test methods are the following few ways.

What about precision injection molding?

Compared with the traditional technology, Cn-moulding has higher precision plastic injection molding and more perfect performance, which is often supplied to electronic information engineering, medical devices , packaging, refrigerators , Automotive , hardware, apparatus, timepiece industry, weapons, and aerospace, etc. Therefore, it will become a revolution between parts molding and processing