Automotive injection mold manufacturing industry

Automotive Injection Molding

2021年6月18日

How to Complete a Project for Plastic Injection Molding Quotes

2021年6月24日Automobile Industry Drive China Injection Mould Manufacturing

Auto injection mold is still the widest manufacturing in china. The field of industrial development is rapid, every new car invest need thousands of pair of injection molds. Automakers have formed with the closest matching. The mould enterprise development, research and debugging technology, production of strategic alliance.

Automotive is an increasingly high-strength plate in order to reduce weight. It is also for some ultra high strength plate hot forming and the corresponding hot forming. And mold has naturally become a development trend.

Automotive Industrial to use plastic ratio will increase and the development of new materials. It is including all kinds of new plastic, modified plastic, metal, plastic, magnesium alloy, composite material, and so on. Then it requires a new forming technology, which also requires that have adapted to the new mold.

According to CNMOULDING company analysis, plastic part manufacturing is the future in the market. The proportion of total plastic mold in china will gradually increase. Its development speed will be higher than other mold manufacturers.

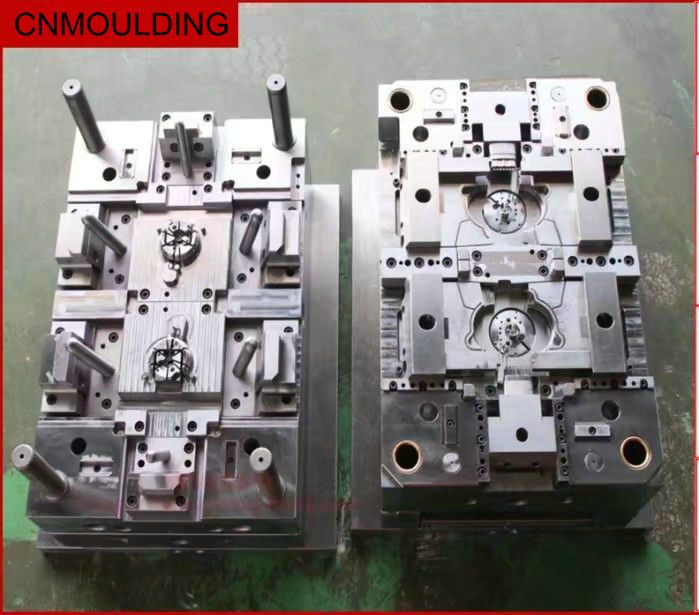

Intelligent and composite technology applications for automotive injection mold production

“Automotive Injection mold to elegant requires good appearance generous, internal defects, this would require careful, precision injection mold with high quality. At present, the refinement has a big gap, refinement is often ignored by some companies, the results fell short.”

The company, I think that the injection mold fast and efficient production. The injection molding enterprises try to shorten the mold production cycle time, to plastic molding the user mould as soon as possible. On the other hand, is more important, the user can provide an injection mold to produce products more quickly and efficiently.

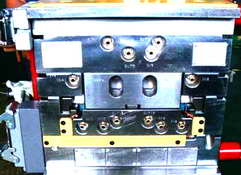

Such as more than a multi-cavity mould production, laminated mold, forming time, and make good use of hot runner technology to shorten the use of multilayer composite technology. Since mould decoration technology, highlights non-mark injection molding technology, testing technology and process of composite technology and transfer technology, and so on. At the same time, stamping forming process intelligence also requires an intelligent mold to adapt.

Precision Injection mold market in the automotive sector

Precision injection mold, we call PIM here. Along with the progress of production technology, the automobile industry also is an important application field of PIM technology. Gearbox, engine, locking mechanism, turbocharger, steering system. And various electronic systems embedded in automotive injection molded parts, are very powerful and highly complex.

Automotive industry in the 2020 market, PIM has accounted for more than 21% of the market share, an increase of 10.4%。Including forecast analysis data and digital map data. The use of finely dispersed powders helps to produce a highly uniform microstructure, which helps to significantly improve the microstructure of investment casting products needed in the automotive industry. These factors significantly affect the PIM market growth