Automotive Plastic Parts Manufacturers

Injection Mold Quote

2021年7月7日Automotive Plastic Parts Manufacturers Expert

Automotive plastic parts manufacturers are one of the fastest developing and most advanced manufacturing industries in China today. Relying on the perfect high-quality injection plastic parts to improve the vehicle’s beauty, safety, and reduce the impact on the environment. Especially for electric vehicles, the new automotive technology development continues to improve, and then improve.

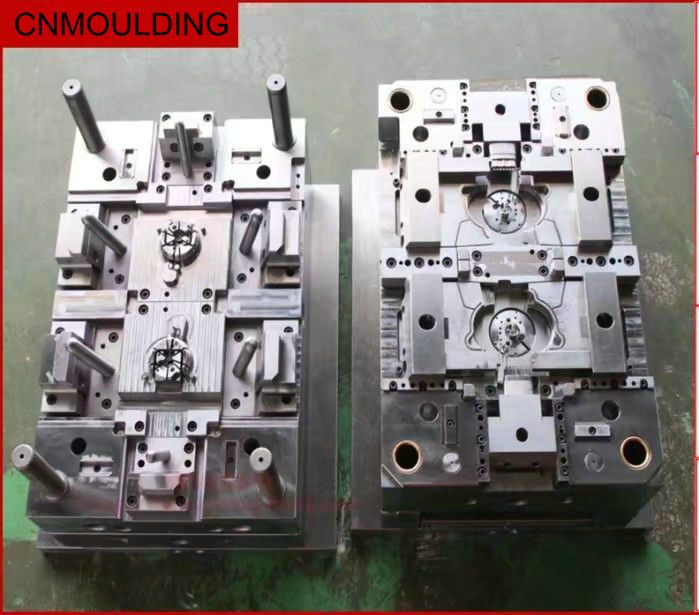

That is why CNMOULDING engineers from major automotive plastic parts manufacturers, offer complete solution homes to their customers. This includes material selection and performance, prototype sample production, mold manufacturing, tolerances, quality control, and more.

More efficient production

The number of vehicles users number increases every year due to the versatility and automotive plastic parts lightweight. In fact, the new plastic technology benefits the car manufacturing process in many ways. It is possible for car manufacturers to build a car from scratch in one day.

This is impossible for components not made by injection molding. We have played a great role in the design and manufacture of many cars, and we are experts in automotive plastic molding. Relying on our 30 years of experience. Automotive injection tooling and inspection suit business, creation, and innovation originate from our profession.

Design and Material

Electric vehicles will be the automotive production future development trend. The demand for injection plastic parts in electric vehicle applications is very large, and the product design is becoming more and more complex. At the same time, the product accuracy is also getting higher and higher, and the materials are also getting more and more special. Only a top-level engineering team can withstand this challenge.

In response to this trend, the CNMOULDING team shared the thousands of materials choices, providing designers with specific physical properties such as strength, flexibility, temperature, corrosion and oxidation, flame retardant, and UV resistance. As a material science and injection molding expert,

Combine our team experience to help improve the optimized design and performance target materials. Such professional services achieve the most effective results in design, material selection, and plastic properties.

Outstanding production expertise and manufacturing experience in the automotive field

1.External plastic auto parts

Bumpers, brackets, blinds, fenders

2. Interior trim parts

Seat, door panel, center console

3.Decorative automotive plastic parts

Nameplate, interior, and exterior trim, border,