Refrigerator Plastic Parts Injection Molding and Mold Making

What about a Hot Runner Mould

2021年6月11日

Refrigerator Mould

2021年6月16日Plastic Injection Molding and Mold Making

Civil refrigerator plastic part and home refrigeration are used in high-end cars , RV and house , including eight parts,

namely:

- compressor cooling hole

- power interface

- fuse

- digital LCD display

- Touch control panel

- hidden handle

- sealant ring

- refrigerator cavity.

At CNMOULDING Precision Mould, our engineers work with Automotive Refrigeration or household refrigerators Company to design, manufacture, injection molding to develop custom plastic parts from the ability to ensure oxidation resistance and low temperature resistance. Most importantly, our plastic components are not only FDA certified, but also environmentally friendly biodegradable materials.

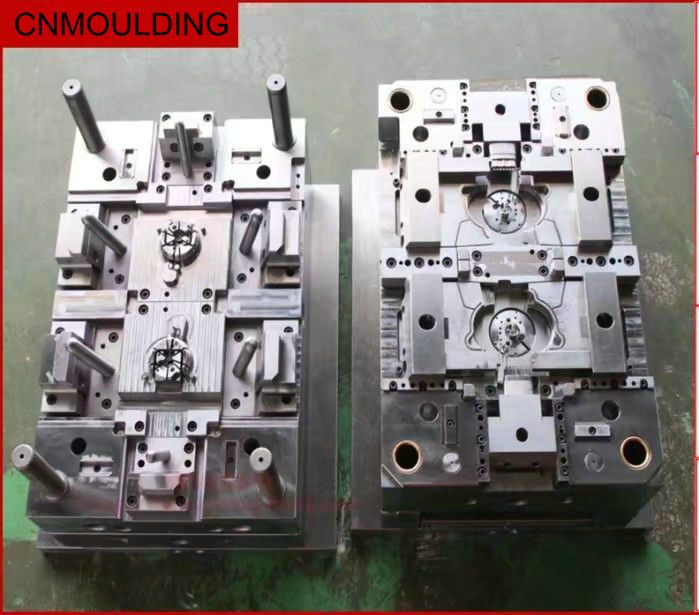

Mold Making for Refrigerator Plastic Parts

Mold Making is the process of forming and billet tools, including cutting and milling molds, which usually consists of core and cavity modes. Place the steel plate between the mold and realize the molding of the material under the press, when the pressure opens the shape of the mold or remove the corresponding scrap. Small to the electronic connector to the automotive instrument panel can be formed with the mold. For the refrigerator mold making is a one-time cost, the investment is high. Experienced, trusted supplier is that this custom mold development has become reassuring. Take the injection mold of the refrigerator drawer box as an example。

Injection Molding In Refrigerator Plastic Parts

Injection Molding is the most commonly used manufacturing process for the fabrication of plastic parts. A wide variety of products are manufactured using injection molding, which varies greatly in their size, complexity, and application.

Refrigerator Plastic Parts manufacturing process requires the use an injection molding machine, raw plastic material, and a mold. The plastic is melted in the injection molding machine and then injected into the mold, where it cools and solidifies into the final part. The steps in this process are described in greater detail in the next section.