Three ways to find a good Chinese injection molding supplier

What time to select the injection molding supplier? However, if we want to have a substantive discussion and ask for that, before making your decision, look at our proposal, you must be inspired.

The main reason, American and European companies source injection molding products in China.

It is not the price factor, but the Chinese have a mature industry supply chain.

From mold making to the supply of raw materials. From paint products to laser engraving and final assembly work.

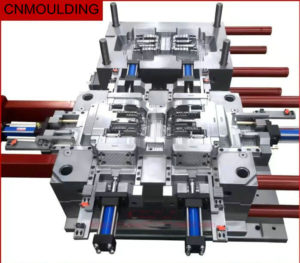

1. To investigate injection molding suppliers whether they have their mold shop?

A quality injection molding supplier does not need to have a lot of workers, more need to have a quality team to support the whole system operation. More than 50 injection mold suppliers can not make quality mold, they are only in wholesale. this model is not suitable for high-tech injection mold suppliers, the cost is too high to recruit good engineers.

Many customers do not understand the injection molding manufacturing business to save costs. In the early stage of product development, looking for a simple factory make tools, just for a cheap price. Then when they send the mold to our factory, engineers told him you bought a toy back, not tools/molds.

2. Good project production planning.

Regardless of project size, injection mold suppliers make a plan that is the ability to control the whole process. From raw materials preparation, printing and packaging products. Customers’ job is to regularly check the schedule of the project execution.

Developed Internet hardware and software to provide a guarantee for global procurement. China injection mold suppliers also benefit from this, and at any time to provide customers with technical, progress reports.

3. Mold manufacturer have nice Quality and Validation Systems

Do not confuse injection mold supplier by an ISO9000 or QS2000 certification paper, It is only a piece of paper that can be bought in China. Do not give a few projectors, three coordinate measuring machine to deceive your judgment, it can be bought with money also.

What is accumulated by an enterprise, through years of experience to get it? the answer is a company’s unique quality management team, as well as from the reputation of its customers?

As the plastic injection molding supplier in China, CNmoulding provide solutions to the production of a full set of products, my team motto ” quality, quality, and quality in mind every day, to ensure customer satisfaction, we can survive” through our unremitting efforts to customers fully trust our products and services, he/she will be back to do business with us, and even we recommend to other companies.

Adequate protection of intellectual property rights by injection molding suppliers

At the same time, your intellectual property rights are fully protected, we earn the profits of enterprises while ensuring that our customers because of the good quality to get them more in return.

If you are not the first time to buy plastic injection molded parts, I believe there must have been a bad experience. The experiences are usually paid for at a higher price. There are too many cases, poor quality, delivery, service, and technical support is not good.

The only important to the injection molding supplier is their receivables. We have cooperated with the United States, Canada, Australia, and the European Union partners, for all of the injection molding suppliers, for your survival.

To go a long way to improve our executive ability, which can adapt to global procurement now?

My colleague, are you ready to serve the world?