Elbow Injection Mold

How to control plastic injection moulding temperature

2020年10月10日

PET polyester plastic

2020年11月12日Elbow Injection Mold Design For Plastic Parts

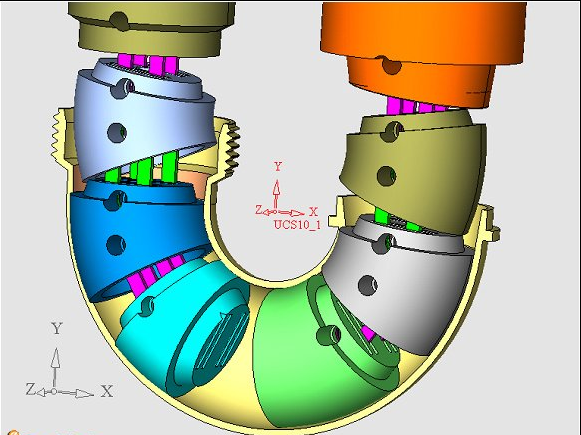

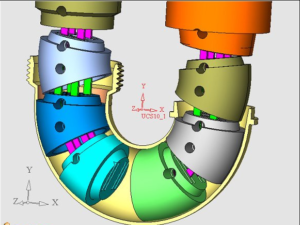

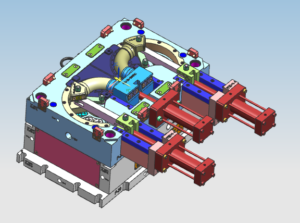

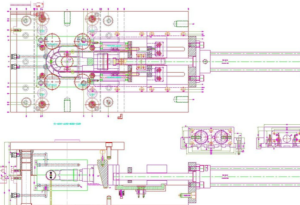

Elbow Mold Design

The injection mold design adopts 1 slider, that is,1 rotating 180-degree slider and linear sliders with hydraulic drive, combined with connecting rod mechanism and gear mechanism.

Elbow plastic injection mold design

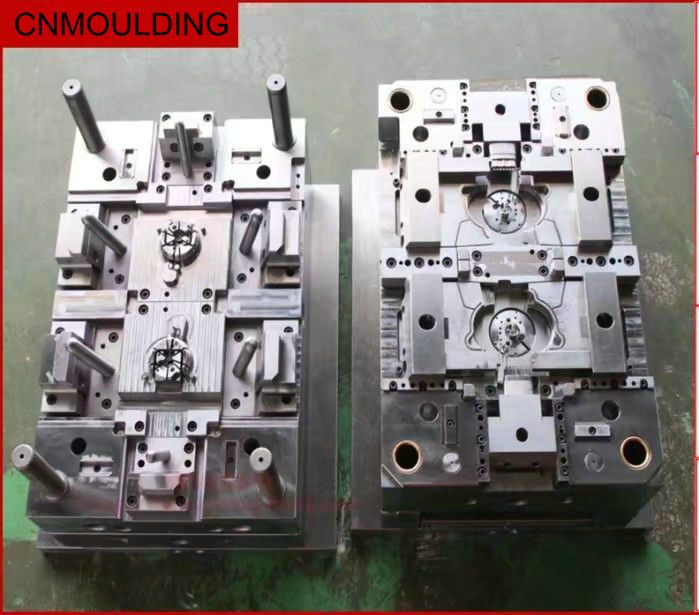

Elbow injection mold manufacturing

Injection Mould Design Structure:

Sliders:6

Slider type:4 line sliders and 2 rotary sliders

Slider drive :3 sliders with corner pins,1 by hydraulic cylinder and other linkage mechanisms

Mechanism: Slider crank mechanism

Injection Molding Mold Design concept:

Sliders: 6

Slider driving: Angle pin, hydraulic cylinder,

Mechanism: Gear + hydraulic mechanism

How to make an elbow mold?

CNMOULDING provides a wide range of elbow mold processing and related services

Many customers not only need 90-degree elbow mold processing. they also need to choose other processes for the production process.

One stage is ready. In addition to NC machining, we can also make, roll and deburr and carve elbow molds

Engraving and assembling.

Why use us for your mold making?

In addition to completing the production operation of various sizes, we are able to create molds for almost any elbow plastic product project. We are used to working with our customers, listening carefully to what they are looking for, and then come up with a suitable solution, which is also feasible and cost-effective.

The accurate and fast injection mold processing

If you need a high-skilled mold and plastic injection company with rich experience in the elbow mold field, CNMOULDING help here. we are an experienced company with advanced equipment and skilled labor that requires accurate manufacturing of complex elbow plastic products from a wide range of materials. if precision and attention to detail are critical to the success of your project, we can deliver according to your exact specifications.