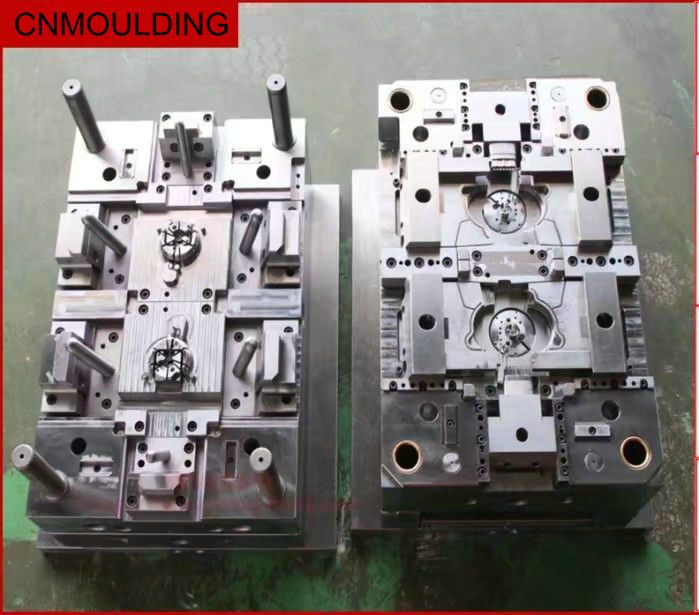

Prototype Mold

Molding Flash

2020年6月30日

Five technological ingenuity to solve injection molding plastic deformation method

2020年6月30日Rapid Prototype mold making for Low-Volume Injection Molds & Products

China injection molding additional service about prototype mold making. It is beginning to the end injection molds manufacturing within 2-3 weeks!

we provide ready-to-shoot Aluminum or steel tools for customers who need production-grade injection molded parts in short order. For our customers who cannot wait 6 weeks for traditional or offshore tooling to be made, we offer Rapid Prototype mold, Low-Volume Injection Mold Tooling, and Parts.

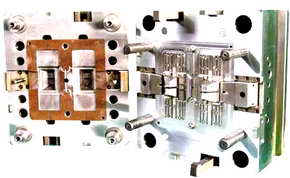

Compare with normal rapid prototyping, Rapid prototyping processes are ok for testing form and fit, but FDM, SLA, and the others are no substitute for testing with real injection molded parts, Low-Volume Injection Mold Tooling & Parts has no geometry limits on part dimensions and allows any commercially available material and surface finish.

Low volume injection molded parts or short-run injection molding Highlights

- An Excellent option for rapid prototype mold projects to combat FDM, SLA rapid prototyping offshore tooling

- No geometry or part structure limits on part dimensions

- high precision critical tolerances are +/- 0.02mm

- quickly service within 2-3 weeks

- Available for all kind of material and surface finish

- it’s great to have a way to make those 100, 1000 or 10,000 parts for pilot production or market testing

The benefit of prototype mold making

If you are not sure that the design has best met the functionality, or if you are not sure whether the final product you want is well assembled. It is risky to make the prototype mold directly.

When you not sure that the design is best suited to the function, or if you are not sure whether the final product you want is well assembled. This may lead to a complete failure of the project development. Prototypes mold making provide you with a way to provide you with an effective and cost-effective assessment.

It is taking the risk of a simple mold. Many companies are not sure how to launch new products at an early stage. This is when a prototype mold can help you determine what is feasible and when you need to redesign it. Because you use low-cost materials and a faster process. You don’t feel the pressure start over!